- Socket Weld Fitting

- Screwed-Threaded Fitting

- Stainless Steel Forged Fitting

- Duplex steel forged fitting

- Carbon Steel Forged Fitting

- Alloy Steel Forged Fitting

- Copper Nickel Forged Fittings

- Alloy 20 Forged Fitting

- Hostellay Forged Fitting

- Inconel Forged Fitting

- Monel Forged Fitting

- Titanium Forged Fitting

- Male Connector

- Female Connector

- Union

- Reducing Union

- Bulk Head Male Connector

- Bulk Head Female Connector

- Bulk Head Union

- Tube End Closure (Cap)

- Fitting End Closure

- Union Elbow

- Male Elbow

- Reducer

- Female Elbow

- Female Adaptor

- Male Adaptor

- Union Cross

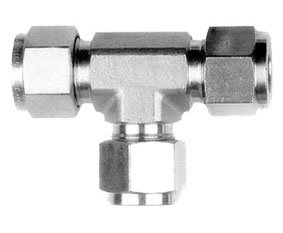

- Union Tee

- Male Branch Tee

- Male Run Tee

- Nut

- Ferrules

Socket Weld Fitting

Socket Weld Fittings Manufacturer & Supplier

Manufacting high-class Socket Weld Fittings, Stainless Steel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Socket Weld Fittings, forged steel fittings, Stainless Steel socket weld fittings, Stainless Steel threaded pipe fittings, Stainless Steel socket weld pipe fittings, Stainless Steel socket fitting, Stainless Steel socket weld fitting, Stainless Steel socket welded fittings, Stainless Steel socket welding fittings, Stainless Steel socket fittings, Stainless Steel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Socket Weld Fittings, 10% sale on Socket Weld Fittings only on 500 pcs.

- Asian Metal Exports is Specialist manufacturer, exporter & supplier of Socket Weld Fittings known for competitive pricing & require minimum time to deliver Socket Weld Fittings at you doorstep. Socket Weld Fittings are electroplated to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Socket Weld Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Socket Weld Fittings in your application.

- Our Socket Weld Fittings come in a variety of classes and material grades for any application. Stainless Steel Socket Weld fittings are available in class 3000, 6000 and 9000. Stainless Steel Threaded fittings are available in class 2000, 3000, and 6000. Socket Weld Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Stainless Steel Threaded couplings, Stainless Steel reducers, Stainless Steel unions, Stainless Steel half couplings and Stainless Steel caps are available in class 3000 and 6000. Stainless Steel Socket Weld couplings, Stainless Steel reducers, Stainless Steel half couplings and Stainless Steel reducer inserts are available in class 3000, 6000 and 9000.

- Socket Weld Fittings Specifications

| Material | Size | Sch. & Swg. | Socket Weld Fittings Specification | Items |

|---|---|---|---|---|

| Socket Weld Fittings | 15 NB to 100 NB (DN6~DN100) | Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and 6000 LBS

A-182

ANSI B16.11

S/W & SCRD

(As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Screwed-Threaded Fitting

Screwed-Threaded Fittings Manufacturer & Supplier

Manufacting high-class Screwed-Threaded Fittings, Stainless steel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Screwed-Threaded Fittings, forged steel fittings, Stainless steel socket weld fittings, Stainless steel threaded pipe fittings, Stainless steel socket weld pipe fittings, Stainless steel socket fitting, Stainless steel socket weld fitting, Stainless steel socket welded fittings, Stainless steel socket welding fittings, Stainless steel socket fittings, Stainless steel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Screwed-Threaded Fittings, 10% sale on Screwed-Threaded Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Screwed-Threaded Fittings known for competitive pricing & require minimum time to deliver Screwed-Threaded Fittings at you doorstep. Screwed-Threaded Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Screwed-Threaded Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Screwed-Threaded Fittings in your application.

- Our Screwed-Threaded Fittings come in a variety of classes and material grades for any application. Stainless steel Socket Weld fittingsare available in class 3000, 6000 and 9000. ttings-manufacturer/”>Stainless steel Threaded fittings are available in class 2000, 3000, and 6000. Screwed-Threaded Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Stainless steel Threaded couplings, Stainless steel reducers, Stainless steel unions, Stainless steel half couplings and Stainless steel caps are available in class 3000 and 6000. Stainless steel Socket Weld couplings, Stainless steel reducers, Stainless steel half couplings and Stainless steel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | Screwed-Threaded Fittings Specification | Items |

|---|---|---|---|---|

| Screwed-Threaded Fittings | 15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings: 3000, 6000 and

9000 LBS Threaded fittings: 2000, 3000, and 6000 LBS |

A-182

ANSI B16.11 S/W & SCRD (As per Gauge) (NPT / BSP / BSPT) |

Elbow – 90° & 45°

Tee – Equal & Reducing Union Cross Coupling (Full, Half & Quick Release) Socket (Reducing) CAP Plug-Hex & Square, Nipples (Hex/Reducing) Bushing Sokolet, Weldolet, Thredolet, Elbolet & Nipolet |

Note –

Grade : 304, 304L, 304H, 316, 316L, 316LN, 316Ti, 309, 310S, 317L, 321, 347, 410, 420, 440C, 202 etc.

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : Reducing Tees

Multiple end configurations

Special length couplings

As per your drawing

High quality Screwed-Threaded Fittings : At Boston Export, all Screwed-Threaded Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : Korean Origin, European Origin, Japanese Origin, US Origin, Indian Origin

We procure raw materials from Europe, Japan, Korea, India and US Origin to produce Screwed-Threaded Fittings

Stainless Steel Forged Fitting

Stainless Steel Forged Fittings Manufacturer & Supplier

- Manufacting high-class Stainless Steel Forged Fittings, Stainless Steel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Stainless Steel Forged Fittings, forged steel fittings, Stainless Steel socket weld fittings, Stainless Steel threaded pipe fittings, Stainless Steel socket weld pipe fittings, Stainless Steel socket fitting, Stainless Steel socket weld fitting, Stainless Steel socket welded fittings, Stainless Steel socket welding fittings, Stainless Steel socket fittings, Stainless Steel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Stainless Steel Forged Fittings, 10% sale on Stainless Steel Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Stainless Steel Forged Fittings known for competitive pricing & require minimum time to deliver Stainless Steel Forged Fittings at you doorstep. Stainless Steel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Stainless Steel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Stainless Steel Forged Fittings in your application.

- Our Stainless Steel Forged Fittings come in a variety of classes and material grades for any application. Stainless Steel Socket Weld fittings are available in class 3000, 6000 and 9000.Stainless Steel Threaded fittings are available in class 2000, 3000, and 6000. Stainless Steel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Stainless Steel Threaded couplings, Stainless Steel reducers, Stainless Steel unions, Stainless Steel half couplings and Stainless Steel caps are available in class 3000 and 6000. Stainless Steel Socket Weld couplings, Stainless Steel reducers, Stainless Steel half couplings and Stainless Steel reducer inserts are available in class 3000, 6000 and 9000

| Material | Size | Sch. & Swg. | Stainless Steel Forged Fittings Specification | Items |

|---|---|---|---|---|

| Stainless Steel

Forged Fittings |

15 NB to

100 NB (DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182 ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Note –

Grade : 304, 304L, 304H, 316, 316L, 316LN, 316Ti, 309, 310S, 317L, 321, 347, 410, 420, 440C, 202 etc.

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : Reducing Tees

Multiple end configurations

Special length couplings

As per your drawing

High quality Stainless Steel Forged Fittings : At Boston Export, all Stainless Steel Forged Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : Korean Origin, European Origin, Japanese Origin, US Origin, Indian Origin

We procure raw materials from Europe, Japan, Korea, India and US Origin to produce Stainless Steel Forged Fittings

Boston Export is the only company in INDIA can arrange fastest delivery of Stainless Steel Forged Fittings to Middle East, Africa, Asia & Far East countries because of availabilty of Stainless Steel Forged Fittings in various size range & different pressure as well as our dealer network in Middle East, Africa, Asia & Far East countries.

Duplex steel forged fitting

Duplex Steel Forged Fittings Manufacturer & Supplier

Manufacting high-class Duplex Steel Forged Fittings, Duplex Steel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Duplex Steel Forged Fittings, forged steel fittings, Duplex Steel socket weld fittings, Duplex Steel threaded pipe fittings, Duplex Steel socket weld pipe fittings, Duplex Steel socket fitting, Duplex Steel socket weld fitting, Duplex Steel socket welded fittings, Duplex Steel socket welding fittings, Duplex Steel socket fittings, Duplex Steel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Duplex Steel Forged Fittings, 10% sale on Duplex Steel Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Duplex Steel Forged Fittings known for competitive pricing & require minimum time to deliver Duplex Steel Forged Fittings at you doorstep. Duplex Steel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Duplex Steel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Duplex Steel Forged Fittings in your application.Our Duplex Steel Forged Fittings come in a variety of classes and material grades for any application. Duplex Steel Socket Weld fittings are available in class 3000, 6000 and 9000. Duplex Steel Threaded fittings are available in class 2000, 3000, and 6000. Duplex Steel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.Duplex Steel Threaded couplings, Duplex Steel reducers, Duplex Steel unions, Duplex Steel half couplings and Duplex Steel caps are available in class 3000 and 6000. Duplex Steel Socket Weld couplings, Duplex Steel reducers, Duplex Steel half couplings and Duplex Steel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | Duplex Steel Forged Fittings Specification | Items |

|---|---|---|---|---|

| Duplex Steel Forged Fittings | 15 NB to

100 NB (DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Note :

Grade : S31200 DUPLEX,S31803 DUPLEX,2205 DUPLEX,SUPER DUPLEX FERRALIUM 225,SUPER DUPLEX 2507,SUPER DUPLEX ZERON 100

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : Multiple end configurations

Special length couplings

As per your drawing

High quality Duplex Steel Forged Fittings : At Boston Export, all Duplex Steel Forged Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : Korean Origin, European Origin, Japanese Origin, US Origin, Indian Origin

We procure raw materials from Europe, Japan, Korea, India and US Origin to produce Duplex Steel Forged Fittings

Boston Export is the only company in INDIA can arrange fastest delivery of Duplex Steel Forged Fittings to Middle East, Africa, Asia & Far East countries because of availabilty of Duplex Steel Forged Fittings in various size range & different pressure as well as our dealer network in Middle East, Africa, Asia & Far East countries.

Carbon Steel Forged Fitting

ASTM A105 Carbon Steel Forged Fittings Manufacturer & Supplier

Manufacting high-class ASTM A105 Carbon Steel Forged Fittings, ASTM A105 Carbon Steel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy ASTM A105 Carbon Steel Forged Fittings, forged steel fittings, ASTM A105 Carbon Steel socket weld fittings, ASTM A105 Carbon Steel threaded pipe fittings, ASTM A105 Carbon Steel socket weld pipe fittings, ASTM A105 Carbon Steel socket fitting, ASTM A105 Carbon Steel socket weld fitting, ASTM A105 Carbon Steel socket welded fittings, ASTM A105 Carbon Steel socket welding fittings, ASTM A105 Carbon Steel socket fittings, ASTM A105 Carbon Steel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of ASTM A105 Carbon Steel Forged Fittings, 10% sale on ASTM A105 Carbon Steel Forged Fittings only on 500 pcs.

- Boston export is Specialist manufacturer, exporter & supplier of ASTM A105 Carbon Steel Forged Fittings known for competitive pricing & require minimum time to deliver ASTM A105 Carbon Steel Forged Fittings at you doorstep. ASTM A105 Carbon Steel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of ASTM A105 Carbon Steel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of ASTM A105 Carbon Steel Forged Fittings in your application.

- Our ASTM A105 Carbon Steel Forged Fittings come in a variety of classes and material grades for any application. ASTM A105 Carbon Steel Socket Weld fittings are available in class 3000, 6000 and 9000. ASTM A105 Carbon Steel Threaded fittings are available in class 2000, 3000, and 6000. ASTM A105 Carbon Steel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- ASTM A105 Carbon Steel Threaded couplings, ASTM A105 Carbon Steel reducers, ASTM A105 Carbon Steel unions, ASTM A105 Carbon Steel half couplings and ASTM A105 Carbon Steel caps are available in class 3000 and 6000. ASTM A105 Carbon Steel Socket Weld couplings, ASTM A105 Carbon Steel reducers, ASTM A105 Carbon Steel half couplings and ASTM A105 Carbon Steel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | ASTM A105 Carbon Steel Forged Fittings Specification | Items |

|---|---|---|---|---|

| ASTM A105 Carbon Steel

Forged Fittings |

15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000,

and 6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Note :

Grade : A105 Carbon Steel, Alloy Steel, Mild Steel, Black Forged Fittings

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : Reducing Tees

Multiple end configurations

Special length couplings

As per your drawing

High quality ASTM A105 Carbon Steel Forged Fittings : At Boston Export, all ASTM A105 Carbon Steel Forged Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : We procure raw materials from Europe, Japan, Korea, India and US Origin to produce ASTM A105 Carbon Steel Forged Fittings

Boston Export is the only company in INDIA can arrange fastest delivery of ASTM A105 Carbon Steel Forged Fittings to Middle East, Africa, Asia & Far East countries because of availabilty of ASTM A105 Carbon Steel Forged Fittings in various size range & different pressure as well as our dealer network in Middle East, Africa, Asia & Far East countries.

Alloy Steel Forged Fitting

ASTM A182 Alloy Steel Forged Fittings Manufacturer & Supplier

Manufacting high-class ASTM A182 Alloy Steel Forged Fittings, ASTM A182 Alloy Steel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy ASTM A182 Alloy Steel Forged Fittings, forged steel fittings, ASTM A182 Alloy Steel socket weld fittings, ASTM A182 Alloy Steel threaded pipe fittings, ASTM A182 Alloy Steel socket weld pipe fittings, ASTM A182 Alloy Steel socket fitting, ASTM A182 Alloy Steel socket weld fitting, ASTM A182 Alloy Steel socket welded fittings, ASTM A182 Alloy Steel socket welding fittings, ASTM A182 Alloy Steel socket fittings, ASTM A182 Alloy Steel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of ASTM A182 Alloy Steel Forged Fittings, 10% sale on ASTM A182 Alloy Steel Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of ASTM A182 Alloy Steel Forged Fittings known for competitive pricing & require minimum time to deliver ASTM A182 Alloy Steel Forged Fittings at you doorstep. ASTM A182 Alloy Steel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of ASTM A182 Alloy Steel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of ASTM A182 Alloy Steel Forged Fittings in your application.

- Our ASTM A182 Alloy Steel Forged Fittings come in a variety of classes and material grades for any application. ASTM A182 Alloy Steel Socket Weld fittings are available in class 3000, 6000 and 9000. ASTM A182 Alloy Steel Threaded fittings are available in class 2000, 3000, and 6000. ASTM A182 Alloy Steel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- ASTM A182 Alloy Steel Threaded couplings, ASTM A182 Alloy Steel reducers, ASTM A182 Alloy Steel unions, ASTM A182 Alloy Steel half couplings and ASTM A182 Alloy Steel caps are available in class 3000 and 6000. ASTM A182 Alloy Steel Socket Weld couplings, ASTM A182 Alloy Steel reducers, ASTM A182 Alloy Steel half couplings and ASTM A182 Alloy Steel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | ASTM A182 Alloy Steel Forged Fittings Specification | Items |

|---|---|---|---|---|

| ASTM A182 Alloy Steel

Forged Fittings Forged Alloy Steel |

15 NB to

100 NB (DN6~DN100) |

Socket Weld fittings: 3000, 6000 and

9000 LBS Threaded fittings: 2000, 3000, and 6000 LBS |

A-182

ANSI B16.11 S/W & SCRD (As per Gauge) (NPT / BSP / BSPT) |

Elbow – 90° & 45°

Tee – Equal & Reducing Union Cross Coupling (Full, Half & Quick Release) Socket (Reducing) CAP Plug-Hex & Square, Nipples (Hex/Reducing) Bushing Sokolet, Weldolet, Thredolet, Elbolet & Nipolet |

Note –

Grade :

A105 Carbon Steel, Alloy Steel, Mild Steel, Black Forged Fittings

A182 F5, F9, F11, F12, F21, F22 & F91

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Manufacturer Test Certificate / IBR Test Certificate (Form III-C), Under Third Party Inspection & with Excise Gate Pass to avail Modvat benefit.

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : IBR Fittings

Reducing Tees

Multiple end configurations

Special length couplings

As per your drawing

High quality ASTM A182 Alloy Steel Forged Fittings :At PM Metal, all ASTM A182 Alloy Steel Forged Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : We procure raw materials from Europe, Japan, Korea, India and US Origin to produce ASTM A182 Alloy Steel Forged Fittings

Copper Nickel Forged Fittings

Copper Nickel Forged Fittings Manufacturer & Supplier

- Manufacting high-class Copper Nickel Forged Fittings, Copper Nickel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Copper Nickel Forged Fittings, forged steel fittings, Copper Nickel socket weld fittings, Copper Nickel threaded pipe fittings, Copper Nickel socket weld pipe fittings, Copper Nickel socket fitting, Copper Nickel socket weld fitting, Copper Nickel socket welded fittings, Copper Nickel socket welding fittings, Copper Nickel socket fittings, Copper Nickel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Copper Nickel Forged Fittings, 10% sale on Copper Nickel Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Copper Nickel Forged Fittings known for competitive pricing & require minimum time to deliver Copper Nickel Forged Fittings at you doorstep. Copper Nickel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Copper Nickel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Copper Nickel Forged Fittings in your application.

- Our Copper Nickel Forged Fittings come in a variety of classes and material grades for any application. Copper Nickel Socket Weld fittings are available in class 3000, 6000 and 9000. Copper Nickel Threaded fittings are available in class 2000, 3000, and 6000. Copper Nickel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Copper Nickel Threaded couplings, Copper Nickel reducers, Copper Nickel unions, Copper Nickel half couplings and Copper Nickel caps are available in class 3000 and 6000. Copper Nickel Socket Weld couplings, Copper Nickel reducers, Copper Nickel half couplings and Copper Nickel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | Copper Nickel Forged Fittings Specification | Items |

|---|---|---|---|---|

| Copper Nickel

Forged Fittings |

15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000 and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Note :

Grade : Cu-Ni 70/30 (C71500), UNS C71640, Cu-Ni 90/10 (C70600), UNS C71640

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : Reducing Tees

Multiple end configurations

Special length couplings

As per your drawing

Copper Nickel Cu-Ni 90/10 (C70600) Forged Fittings | Copper Nickel Cu-Ni 90/10 (C70600) Forged Tee | Copper Nickel Cu-Ni 90/10 (C70600) Forged Coupling

Copper Nickel Cu-Ni 70/30 (C71500) Forged Fittings | Copper Nickel Cu-Ni 70/30 (C71500) Forged Tee | Copper Nickel Cu-Ni 70/30 (C71500) Forged Coupling

High quality Copper Nickel Forged Fittings : At Boston Export, all Copper Nickel Forged Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : Korean Origin, European Origin, Japanese Origin, US Origin, Indian Origin

We procure raw materials from Europe, Japan, Korea, India and US Origin to produce Copper Nickel Forged Fittings

Boston Export is the only company in INDIA can arrange fastest delivery of Copper Nickel Forged Fittings to Middle East, Africa, Asia & Far East countries because of availabilty of Copper Nickel Forged Fittings in various size range & different pressure as well as our dealer network in Middle East, Africa, Asia & Far East countries.

Alloy 20 Forged Fitting

ASTM B462 Alloy 20 Forged Fittings Manufacturer & Supplier

- Manufacting high-class ASTM B462 Alloy 20 Forged Fittings, ASTM B462 Alloy 20 forged fittings,High Pressure Forged Pipe Fittings in India

- Buy ASTM B462 Alloy 20 Forged Fittings, forged steel fittings, ASTM B462 Alloy 20 socket weld fittings, ASTM B462 Alloy 20 threaded pipe fittings, ASTM B462 Alloy 20 socket weld pipe fittings, ASTM B462 Alloy 20 socket fitting, ASTM B462 Alloy 20 socket weld fitting, ASTM B462 Alloy 20 socket welded fittings, ASTM B462 Alloy 20 socket welding fittings, ASTM B462 Alloy 20 socket fittings, ASTM B462 Alloy 20 socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of ASTM B462 Alloy 20 Forged Fittings, 10% sale on ASTM B462 Alloy 20 Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of ASTM B462 Alloy 20 Forged Fittings known for competitive pricing & require minimum time to deliver ASTM B462 Alloy 20 Forged Fittings at you doorstep. ASTM B462 Alloy 20 Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of ASTM B462 Alloy 20 Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of ASTM B462 Alloy 20 Forged Fittings in your application.

- Our ASTM B462 Alloy 20 Forged Fittings come in a variety of classes and material grades for any application. ASTM B462 Alloy 20 Socket Weld fittings are available in class 3000, 6000 and 9000. ASTM B462 Alloy 20 Threaded Fittings are available in class 2000, 3000, and 6000. ASTM B462 Alloy 20 Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- ASTM B462 Alloy 20 Threaded couplings, ASTM B462 Alloy 20 reducers, ASTM B462 Alloy 20 unions, ASTM B462 Alloy 20 half couplings and ASTM B462 Alloy 20 caps are available in class 3000 and 6000. ASTM B462 Alloy 20 Socket Weld couplings, ASTM B462 Alloy 20 reducers, ASTM B462 Alloy 20 half couplings and ASTM B462 Alloy 20 reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | ASTM B462 Alloy 20 Forged Fittings Specification | Items |

|---|---|---|---|---|

| ASTM B462 Alloy 20

Forged Fittings |

15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Note –

Grade : A105 Carbon Steel, Alloy Steel, Mild Steel, Black Forged Fittings

Test Certificate : Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Dimension Specifications : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Specialize : Reducing Tees

Multiple end configurations

Special length couplings

As per your drawing

High quality ASTM B462 Alloy 20 Forged Fittings : At Boston Export, all ASTM B462 Alloy 20 Forged Fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Origin : Korean Origin, European Origin, Japanese Origin, US Origin, Indian Origin

We procure raw materials from Europe, Japan, Korea, India and US Origin to produce ASTM B462 Alloy 20 Forged Fittings

Boston Export is the only company in INDIA can arrange fastest delivery of ASTM B462 Alloy 20 Forged Fittings to Middle East, Africa, Asia & Far East countries because of availabilty of ASTM B462 Alloy 20 Forged Fittings in various size range & different pressure as well as our dealer network in Middle East, Africa, Asia & Far East countries.

Hostellay Forged Fitting

Hostelloy Forged Fittings Manufacturer & Supplier

- Manufacting high-class Hastelloy Forged Fittings, Hastelloy forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Hastelloy Forged Fittings, forged steel fittings, Hastelloy socket weld fittings, Hastelloy threaded pipe fittings, Hastelloy socket weld pipe fittings, Hastelloy socket fitting, Hastelloy socket weld fitting, Hastelloy socket welded fittings, Hastelloy socket welding fittings, Hastelloy socket fittings, Hastelloy socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Hastelloy Forged Fittings, 10% sale on Hastelloy Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Hastelloy Forged Fittings known for competitive pricing & require minimum time to deliver Hastelloy Forged Fittings at you doorstep. Hastelloy Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Hastelloy Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Hastelloy Forged Fittings in your application.

- Our Hastelloy Forged Fittings come in a variety of classes and material grades for any application.Hastelloy Socket Weld fittings are available in class 3000, 6000 and 9000.Hastelloy Threaded fittings are available in class 2000, 3000, and 6000. Hastelloy Forged Fittingsare manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Hastelloy Threaded couplings, Hastelloy reducers, Hastelloy unions, Hastelloy half couplings and Hastelloy caps are available in class 3000 and 6000. Hastelloy Socket Weld couplings, Hastelloy reducers, Hastelloy half couplings and Hastelloy reducer inserts are available in class 3000, 6000 and 9000.

- Hastelloy C276 is a tungsten added nickel-molybdenum-chromium super alloy designed to offer excellent corrosion resistance in wide range of severe environments. The chromium in Hastelloy C276 conveys resistance to oxidizing media while high molybdenum and nickel content makes the nickel alloy specially resistant to pitting and crevice corrosion in reducing environments.

| Material | Size | Sch. & Swg. | Hastelloy Forged Fittings Specification | Items |

|---|---|---|---|---|

| Hastelloy

Forged Fittings |

15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Inconel Forged Fitting

Inconel Forged Fittings Manufacturer & Supplier

- Manufacting high-class Inconel Forged Fittings, Inconel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Inconel Forged Fittings, forged steel fittings, Inconel socket weld fittings, Inconel threaded pipe fittings, Inconel socket weld pipe fittings, Inconel socket fitting, Inconel socket weld fitting, Inconel socket welded fittings, Inconel socket welding fittings, Inconel socket fittings, Inconel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Inconel Forged Fittings, 10% sale on Inconel Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Inconel Forged Fittings known for competitive pricing & require minimum time to deliver Inconel Forged Fittings at you doorstep. Inconel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Inconel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Inconel Forged Fittings in your application.

- Our Inconel Forged Fittings come in a variety of classes and material grades for any application. Inconel Socket Weld fittings are available in class 3000, 6000 and 9000.Inconel Threaded fittings are available in class 2000, 3000, and 6000. Inconel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Inconel Threaded couplings, Inconel reducers, Inconel unions, Inconel half couplings and Inconel caps are available in class 3000 and 6000. Inconel Socket Weld couplings, Inconel reducers, Inconel half couplings and Inconel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | Inconel Forged Fittings Specification | Items |

|---|---|---|---|---|

| Inconel Forged Fittings | 15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Monel Forged Fitting

Monel Forged Fittings Manufacturer & Supplier

- Manufacting high-class Monel Forged Fittings, Monel forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Monel Forged Fittings, forged steel fittings, Monel socket weld fittings, Monel threaded pipe fittings, Monel socket weld pipe fittings, Monel socket fitting, Monel socket weld fitting, Monel socket welded fittings, Monel socket welding fittings, Monel socket fittings, Monel socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Monel Forged Fittings, 10% sale on Monel Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of known for competitive pricing & require minimum time to deliver Monel Forged Fittings at you doorstep. Monel Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Monel Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Monel Forged Fittings in your application.

- Our Monel Forged Fittings come in a variety of classes and material grades for any application.Monel Socket Weld fittings are available in class 3000, 6000 and 9000.Monel Threaded fittings are available in class 2000, 3000, and 6000.Monel Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Monel Threaded couplings, Monel reducers, Monel unions, Monel half couplings and Monel caps are available in class 3000 and 6000. Monel Socket Weld couplings, Monel reducers, Monel half couplings and Monel reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | Monel Forged Fittings Specification | Items |

|---|---|---|---|---|

| Monel Forged Fittings | 15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Titanium Forged Fitting

Titanium Forged Fittings Manufacturer & Supplier

- Manufacting high-class Titanium Forged Fittings, Titanium forged fittings,High Pressure Forged Pipe Fittings in India

- Buy Titanium Forged Fittings, forged steel fittings, Titanium socket weld fittings, Titanium threaded pipe fittings, Titanium socket weld pipe fittings, Titanium socket fitting, Titanium socket weld fitting, Titanium socket welded fittings, Titanium socket welding fittings, Titanium socket fittings, Titanium socket pipe fittings for perfect connection & critical applications, excellent pricing and extensive size range of Titanium Forged Fittings, 10% sale on Titanium Forged Fittings only on 500 pcs.

- Boston Export is Specialist manufacturer, exporter & supplier of Titanium Forged Fittings known for competitive pricing & require minimum time to deliver Titanium Forged Fittings at you doorstep. Titanium Forged Fittings are electropolished to remove free iron and to provide a high-quality finish & to ensure our forged steel fittings have the highest degree of corrosion resistance. Widest stock & shortest delivery time of Titanium Forged Fittings, 40 years experience in dealing forged steel fittings; free Consultancy for critical application expert advice from industry professional for use of Titanium Forged Fittings in your application.

- Our Titanium Forged Fittings come in a variety of classes and material grades for any application.Titanium Socket Weld fittings are available in class 3000, 6000 and 9000.Titanium Threaded fittings are available in class 2000, 3000, and 6000. Titanium Forged Fittings are manufactured in compliance with ASTM A-403 and ANSI B16.9 / 16.28/ MSS SP-43 / Welding Bevel Standards ANSI B 16.25.

- Titanium Threaded couplings, Titanium reducers, Titanium unions, Titanium half couplings and Titanium caps are available in class 3000 and 6000. Titanium Socket Weld couplings, Titanium reducers, Titanium half couplings and Titanium reducer inserts are available in class 3000, 6000 and 9000.

| Material | Size | Sch. & Swg. | Titanium Forged Fittings Specification | Items |

|---|---|---|---|---|

| Titanium Forged Fittings | 15 NB to 100 NB

(DN6~DN100) |

Socket Weld fittings:

3000, 6000 and 9000 LBS |

Threaded fittings:

2000, 3000, and

6000 LBSA-182

ANSI B16.11 S/W

& SCRD (As per Gauge)

(NPT / BSP / BSPT)Elbow – 90° & 45°

Tee – Equal & Reducing

Union

Cross

Coupling

(Full, Half & Quick Release)

Socket (Reducing)

CAP

Plug-Hex & Square,

Nipples (Hex/Reducing)

Bushing

Sokolet, Weldolet, Thredolet, Elbolet & Nipolet

Male Connector

| METRIC RANGE | Dimention in mm | |||||||||

|

Part

|

T

|

P

|

L1

|

M

|

C

|

D

|

F

|

G

|

H

|

N

|

|

N0

|

mmo/d |

Length

|

Body

|

Nut

|

Body

|

|||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1″ | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1″ | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1″ | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49

|

| METRIC RANGE | Dimention in Inches | |||||||||

|

Part

|

T

|

P

|

L1

|

M

|

C

|

D

|

F

|

G

|

H

|

N

|

|

N0

|

mmo/d |

Length

|

Body

|

Nut

|

Body

|

|||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

Female Connector

| METRIC RANGE | Dimention in Inches | |||||||||

|

Part

|

T

|

P

|

L1

|

M

|

C

|

D

|

F

|

G

|

H

|

|

|

N0

|

mmo/d |

Length

|

Body

|

Nut

|

Body

|

|||||

| 4mFC2 | 4 | 1/8″ | 30.16 | 10 | 16.67 | 14.29 | 14 | 12 | 23.02 | |

| 6mFC2 | 6 | 1/8″ | 31.75 | 10 | 18.26 | 15.88 | 14 | 14 | 23.81 | |

| 6mFC4 | 6 | 1/4″ | 36.51 | 14 | 18.26 | 15.88 | 19 | 14 | 28.58 | |

| 6mFC6 | 6 | 3/8″ | 38.07 | 14 | 18.26 | 15.88 | 22 | 14 | 30.16 | |

| 6mFC8 | 6 | 1/2″ | 43.66 | 19 | 18.26 | 15.88 | 27 | 14 | 35.72 | |

| 8mFC2 | 8 | 1/8″ | 32.54 | 10 | 19.05 | 16.67 | 14 | 17 | 24.61 | |

| 8mFC4 | 8 | 1/4 | 37.31 | 14 | 19.05 | 16.67 | 19 | 17 | 29.37 | |

| 10mFC2 | 10 | 1/8″ | 33.34 | 10 | 19.84 | 17.46 | 17 | 19 | 25.40 | |

| 10mFC4 | 10 | 1/4″ | 38.10 | 14 | 19.84 | 17.46 | 19 | 19 | 30.16 | |

| 10mFC6 | 10 | 3/8″ | 39.69 | 14 | 19.84 | 17.46 | 22 | 19 | 31.75 | |

| 10mFC8 | 10 | 1/2″ | 44.45 | 19 | 19.84 | 17.46 | 27 | 19 | 36.51 | |

| 12mFC4 | 12 | 1/4″ | 42.07 | 14 | 22.23 | 23.02 | 22 | 22 | 31.75 | |

| 12mFC6 | 12 | 3/8″ | 42.07 | 14 | 22.23 | 23.02 | 22 | 22 | 31.75 | |

| 12mFC8 | 12 | 1/2″ | 46.83 | 19 | 22.23 | 23.02 | 27 | 22 | 36.51 | |

| 16mFC8 | 16 | 1/2″ | 46.83 | 19 | 22.23 | 24.61 | 27 | 27 | 36.51 | |

| 18mFC8 | 18 | 1/2″ | 46.83 | 19 | 22.23 | 24.61 | 27 | 30 | 36.51 | |

| 18mFC12 | 18 | 3/4″ | 48.42 | 19 | 22.23 | 24.61 | 32 | 30 | 38.10 | |

| 20mFC8 | 20 | 1/2″ | 46.83 | 19 | 22.23 | 24.61 | 27 | 30 | 36.51 | |

| 20mFC12 | 20 | 3/4″ | 48.42 | 19 | 22.23 | 24.61 | 32 | 30 | 38.10 | |

| 25mFC12 | 25 | 3/4″ | 53.18 | 19 | 26.19 | 31.75 | 36 | 41 | 41.28 | |

| 25mFC16 | 25 | 1′ | 6191 | 24 | 26.19 | 30.96 | 41 | 41 | 50.01 | |

Union

| METRIC RANGE | Dimention in Inches | ||||||

|

Part

|

T

|

L1

|

C

|

D

|

F

|

G

|

H

|

|

N0

|

o/d

|

Length

|

Body

|

Nut

|

Body

|

||

| 4mU | 4 | 38.50 | 16.67 | 14.29 | 12 | 12 | 24.21 |

| 6mU | 6 | 42.07 | 18.26 | 15.88 | 14 | 14 | 26.19 |

| 8mU | 8 | 44.04 | 19.05 | 16.67 | 14 | 17 | 28.18 |

| 10mU | 10 | 46.04 | 19.84 | 17.46 | 17 | 19 | 30.16 |

| 12mU | 12 | 51.59 | 22.23 | 23.01 | 22 | 22 | 30.96 |

| 16mU | 16 | 52.39 | 22.23 | 24.61 | 24 | 27 | 31.75 |

| 18mU | 18 | 53.98 | 22.23 | 24.61 | 27 | 30 | 33.34 |

| 20mU | 20 | 53.98 | 22.23 | 24.61 | 30 | 32 | 33.34 |

| 25mU | 25 | 64.29 | 26.19 | 30.96 | 36 | 41 | 40.48 |

Reducing Union

| METRIC RANGE | Dimentions in Inches | ||||||||

|

Part

|

T1 mm

|

T2 mm

|

L1

|

C1

|

C2

|

F

|

G1

|

G2

|

H

|

|

N0

|

o/d

|

o/d

|

Length

|

Body

|

Nut

|

Nut

|

Body

|

||

| 6-4mRU | 6 | 4 | 40.48 | 19.97 | 19.05 | 14 | 14 | 12 | 25.40 |

| 8-6mRU | 8 | 6 | 43.26 | 19.05 | 19.97 | 14 | 17 | 14 | 27.38 |

| 10-6mRU | 10 | 6 | 44.45 | 19.84 | 19.97 | 17 | 19 | 14 | 28.58 |

| 10-8mRU | 10 | 8 | 45.24 | 19.84 | 19.05 | 17 | 19 | 17 | 29.37 |

| 12-6mRU | 12 | 6 | 47.63 | 22.23 | 19.97 | 22 | 22 | 14 | 29.37 |

| 12-10mRU | 12 | 10 | 49.21 | 22.23 | 19.84 | 22 | 22 | 19 | 30.96 |

| 16-10mRU` | 16 | 10 | 50.01 | 22.23 | 19.84 | 24 | 22 | 19 | 31.75 |

| 16-12mRU | 16 | 12 | 52.39 | 22.23 | 22.23 | 24 | 27 | 22 | 31.75 |

| 20-12mRU | 20 | 12 | 53.98 | 22.23 | 22.23 | 27 | 27 | 22 | 33.34 |

| 20-16mRU | 20 | 16 | 53.98 | 22.23 | 22.23 | 27 | 30 | 27 | 33.34 |

| 25-20mRU | 25 | 20 | 60.32 | 26.19 | 22.23 | 36 | 41 | 30 | 38.10 |

Bulk Head Male Connector

| METRIC RANGE | Dimentions in Inches | ||||||||

|

Part

|

T1 mm

|

T2 mm

|

L1

|

C1

|

C2

|

F

|

G1

|

G2

|

H

|

|

N0

|

o / d

|

o / d

|

Length

|

Body

|

Nut

|

Nut

|

Body

|

||

| 6-4mRU | 6 | 4 | 40.48 | 19.97 | 19.05 | 14 | 14 | 12 | 25.40 |

| 8-6mRU | 8 | 6 | 43.26 | 19.05 | 19.97 | 14 | 17 | 14 | 27.38 |

| 10-6mRU | 10 | 6 | 44.45 | 19.84 | 19.97 | 17 | 19 | 14 | 28.58 |

| 10-8mRU | 10 | 8 | 45.24 | 19.84 | 19.05 | 17 | 19 | 17 | 29.37 |

| 12-6mRU | 12 | 6 | 47.63 | 22.23 | 19.97 | 22 | 22 | 14 | 29.37 |

| 12-10mRU | 12 | 10 | 49.21 | 22.23 | 19.84 | 22 | 22 | 19 | 30.96 |

| 16-10mRU` | 16 | 10 | 50.01 | 22.23 | 19.84 | 24 | 22 | 19 | 31.75 |

| 16-12mRU | 16 | 12 | 52.39 | 22.23 | 22.23 | 24 | 27 | 22 | 31.75 |

| 20-12mRU | 20 | 12 | 53.98 | 22.23 | 22.23 | 27 | 27 | 22 | 33.34 |

| 20-16mRU | 20 | 16 | 53.98 | 22.23 | 22.23 | 27 | 30 | 27 | 33.34 |

| 25-20mRU | 25 | 20 | 60.32 | 26.19 | 22.23 | 36 | 41 | 30 | 38.10 |

Bulk Head Female Connector

| IMPERIAL RANGE | Dimentions in Inches | ||||||||

|

Part

|

T1

|

T2

|

L1

|

C1

|

C2

|

F

|

G1

|

G2

|

H

|

|

N0

|

o / d

|

o / d

|

Length

|

Body

|

Nut

|

Nut

|

Body

|

||

| 2RU1 | 1/8 | 1/16 | 1.25 | 0.63 | 0.44 | 1/2 | 7/16 | 5/16 | 0.81 |

| 3RU2 | 3/16 | 1/8 | 1.48 | 0.66 | 0.63 | 1/2 | 1/2 | 7/16 | 0.92 |

| 4RU1 | 1/4 | 1/16 | 1.37 | 0.72 | 0.44 | 1/2 | 9/16 | 5/16 | 0.91 |

| 4RU2 | 1/4 | 1/8 | 1.56 | 0.72 | 0.63 | 1/2 | 9/16 | 7/16 | 0.97 |

| 4RU3 | 1/4 | 3/16 | 1.55 | 0.70 | 0.63 | 1/2 | 9/16 | 1/2 | 1.00 |

| 5RU4 | 5/16 | 1/4 | 1.66 | 0.73 | 0.70 | 9/16 | 5/8 | 9/16 | 1.08 |

| 6RU4 | 3/8 | 1/4 | 1.70 | 0.76 | 0.70 | 5/8 | 11/16 | 9/16 | 1.12 |

| 6RU5 | 3/B | 5/16 | 1.74 | 0.76 | 0.73 | 5/8 | 11/16 | 5/8 | 1.16 |

| 8RU4 | 1/2 | 1/4 | 1.85 | 0.86 | 0.70 | 13/16 | 7/8 | 9/16 | 1.16 |

| 8RU6 | 1/2 | 3/B | 1.91 | 0.86 | 0.76 | 13/16 | 7/8 | 11/16 | 1.22 |

| 10RU6 | 5/8 | 3/8 | 1.94 | 0.86 | 0.76 | 15/16 | 1 | 11/16 | 1.25 |

| 10RU8 | 5/8 | 1/2 | 2.05 | 0.86 | 0.86 | 15/16 | 1 | 7/8 | 1.25 |

| 12RU8 | 3/4 | 1/2 | 2.11 | 0.86 | 0.86 | 1-1/16 | 1-1/8 | 7/8 | 1.31 |

| 12RU10 | 3/4 | 5/8 | 2.11 | 0.86 | 0.86 | 1-1/16 | 1-1/8 | 1 | 1.31 |

| 16RU12 | 1 | 3/4 | 2.47 | 1.04 | 0.86 | 1-3/8 | 1-1/2 | 1-1/8 | 1.59 |

Bulk Head Union

METRIC RANGE

| Dimentions in Inches | |||||||||

|

Part

|

T

|

L1

|

C

|

D

|

F

|

G

|

H

|

J

|

L

|

|

N0

|

o / d

|

Length |

Bodycheck nut

|

Nut

|

Body

|

||||

| 4mBHU | 4 | 54.77 | 16.67 | 14.30 | 14 | 12 | 40.48 | 32.54 | 25.40 |

| 6mBHU | 6 | 58.74 | 18.26 | 15.88 | 17 | 14 | 42.86 | 34.13 | 26.10 |

| 8mBHU | 8 | 61.91 | 19.05 | 16.67 | 17 | 17 | 46.04 | 36.51 | 28.50 |

| 10mBHU | 10 | 63.50 | 19.84 | 17.46 | 19 | 19 | 47.63 | 37.71 | 29.30 |

| 12mBHU | 12 | 71.44 | 22.23 | 23.02 | 24 | 22 | 50.80 | 42.07 | 31.70 |

| 16m8HU | 16 | 73.03 | 22.23 | 24.61 | 27 | 27 | 50.80 | 42.86 | 32.50 |

| 18mBHU | 18 | 73.03 | 22.23 | 24.61 | 30 | 30 | 58.74 | 47.63 | 37.30 |

| 20mBHU | 20 | 79.38 | 22.23 | 24.61 | 30 | 30 | 58.74 | 47.63 | 37.30 |

| 25mBHU | 25 | 95.25 | 26.19 | 30.96 | 41 | 41 | 71.44 | 57.15 | 45.20 |

Tube End Closure (Cap)

| METRIC RANGE | Dimentions in Inches | ||||||

|

Part

|

T

|

L1

|

C

|

D

|

F

|

G

|

H

|

|

N0

|

o / d

|

Length |

Body

|

Nut

|

Body

|

||

| 4mTC | 4 | 21.83 | 16.67 | 14.29 | 12 | 12 | 14.68 |

| 6mTC | 6 | 23.81 | 18326 | 15.88 | 14 | 14 | 15.88 |

| 8mTC | 8 | 25.00 | 19.85 | 16.67 | 14 | 17 | 17.67 |

| 1UmTC | 10 | 26.19 | 19.84 | 17.46 | 17 | 19 | 18.26 |

| 12mTC | 12 | 29.37 | 22.23 | 23.02 | 22 | 22 | 19.05 |

| 16mTC | 16 | 30.16 | 22.23 | 24.61 | 24 | 27 | 19.84 |

| 18mTC | 18 | 31.75 | 22.23 | 24.61 | 27 | 30 | 21.43 |

| 20mTC | 20 | 31.75 | 22.23 | 24.61 | 27 | 30 | 21.43 |

| 25mTC | 25 | 36.10 | 26.19 | 30.96 | 36 | 41 | 26.19 |

Fitting End Closure

| METRIC RANGE |

Dimensions in mm

|

|

|

Part

|

T

|

G

|

|

N0

|

o / d

|

Nut

|

| 4mFC | 4 | 12 |

| 6mFC | 6 | 14 |

| 8mFC | 8 | 17 |

| 10mFC | 10 | 19 |

| 12mFC | 12 | 22 |

| 16mFC | 16 | 27 |

| 18mFC | 18 | 30 |

| 20mFC | 20 | 30 |

| 25mFC | 25 | 41 |

Union Elbow

| METRIC RANGE | Dimentions in Inches | |||||

|

Part

|

T

|

L1

|

D

|

F

|

G

|

H

|

|

N0

|

o / d

|

Length |

Body

|

Nut

|

Body

|

|

| 4mELU | 4 | 24.61 | 14.29 | 12 | 12 | 19.05 |

| 6mELU | 6 | 26.19 | 15.88 | 12 | 14 | 19.81 |

| 8mELU | 8 | 29.59 | 16.67 | 14 | 17 | 22.23 |

| 10mELU | 10 | 29.97 | 17.46 | 14 | 19 | 23.11 |

| 12mELU | 12 | 34.93 | 23.02 | 19 | 22 | 24.89 |

| 16mELU | 16 | 96.51 | 24.61 | 24 | 27 | 26.19 |

| 1BmELU | 18 | 39.69 | 24.61 | 27 | 30 | 29.97 |

| 20mELU | 20 | 99.69 | 24.61 | 27 | 30 | 29.97 |

| 25mELU | 25 | 45.24 | 30.96 | 32 | 41 | 33.34 |

Male Elbow

| METRIC RANGE | Dimention in mm | ||||||||

|

Part

|

T

|

P

|

L1

|

M

|

C

|

D

|

F

|

G

|

H

|

|

N0

|

mm / a |

Length

|

Body

|

Nut

|

Body

|

||||

| 4mME2 | 4 | 1/8″ | 24.61 | 19.53 | 19.30 | 14.29 | 12 | 12 | 19.05 |

| 6mME2 | 6 | 1/8″ | 26.19 | 09.53 | 19.84 | 15.88 | 12 | 14 | 19.80 |

| 6mME4 | 6 | 1/4″ | 26.19 | 14.29 | 23.81 | 15.88 | 12 | 14 | 19.80 |

| 6mME6 | 6 | 3/8″ | 27.60 | 14.29 | 23.58 | 15.88 | 14 | 14 | 21.33 |

| 6mME8 | 6 | 1/2″ | 29.40 | 19.05 | 33.24 | 15.88 | 19 | 14 | 23.11 |

| 8mME2 | 8 | 1/8″ | 28.58 | 09.53 | 20.64 | 16.67 | 14 | 17 | 22.22 |

| 8mME4 | 8 | 1/4″ | 28.58 | 14.29 | 25.40 | 16.67 | 14 | 17 | 22.22 |

| 8mME6 | 8 | 3/8″ | 28.58 | 14.24 | 25.40 | 16.67 | 14 | 17 | 22.22 |

| 8mME8 | 8 | 1/2″ | 31.75 | 19.05 | 32.00 | 16.67 | 19 | 17 | 24.00 |

| 10mME2 | 10 | 1/8″ | 28.90 | 09.53 | 22.23 | 17.46 | 14 | 19 | 23.11 |

| 10mME4 | 10 | 1/4″ | 28.90 | 14.29 | 25.40 | 17.46 | 14 | 19 | 23.11 |

| 10mME6 | 10 | 3/8″ | 28.90 | 14.29 | 28.58 | 17.46 | 14 | 19 | 23.11 |

| 10mME8 | 10 | 1/2″ | 30.60 | 19.05 | 31.75 | 17.46 | 19 | 19 | 24.89 |

| 12mME4 | 12 | 1/4″ | 35.80 | 14.29 | 28.58 | 23.02 | 19 | 22 | 24.89 |

| 12mME6 | 12 | 3/8″ | 35.80 | 14.29 | 28.58 | 23.02 | 19 | 22 | 24.89 |

| 12mME8 | 12 | 1/2″ | 35.80 | 19.05 | 33.34 | 23.02 | 19 | 22 | 24.89 |

| 16mME6 | 16 | 3/8″ | 36.51 | 14.29 | 31.75 | 24.61 | 19 | 27 | 26.19 |

| 16mME8 | 16 | 1/2″ | 36.51 | 19.05 | 34.93 | 24.61 | 19 | 27 | 26.19 |

| 18mME8 | 18 | 1/2″ | 39.69 | 19.05 | 38.10 | 24.61 | 27 | 30 | 29.37 |

| 18mME1218 | 18 | 3/8″ | 39.69 | 19.05 | 38.10 | 24.61 | 27 | 30 | 29.37 |

| 20mME8 | 20 | 1/2″ | 39.69 | 19.05 | 38.10 | 24.61 | 27 | 30 | 29.37 |

| 20mME12 | 20 | 3/4″ | 39.69 | 19.05 | 38.10 | 24.61 | 27 | 30 | 29.37 |

| 25mME12 | 25 | 3/4″ | 45.24 | 19.05 | 38.10 | 26.19 | 32 | 41 | 33.34 |

| 25mME16 | 25 | 1″ | 45.24 | 23.81 | 46.83 | 30.96 | 32 | 41 | 33.34 |

Reducer

| IMPERIAL RANGE | Dimention in mm | |||||||

|

Part

|

T

|

T

|

L

|

C

|

D

|

F

|

G

|

H

|

|

N0

|

o / d

|

o / d

|

Body

|

Nut

|

Body

|

|||

| 2RED4 | 11/8 | 1/4 | 1.42 | 0.60 | 0.50 | 7/16 | 7/16 | 1.16 |

| 4RED2 | 1/4 | 1/8 | 1.45 | 0.70 | 0.60 | 1/2 | 9/16 | 1.16 |

| 4RED6 | 1/4 | 3/8 | 1.60 | 0.70 | 0.60 | 1/2 | 9/6 | 1.31 |

| 4RED8 | 1/4 | 1/2 | 1.82 | 0.70 | 0.60 | 9/16 | 9/16 | 1.53 |

| 6RED4 | 3/8 | 1/4 | 1.63 | 0.76 | 0.66 | 5/8 | 11/16 | 1.34 |

| 6RED8 | 3/8 | 1/2 | 1.91 | 0.76 | 0.66 | 5/8 | 11/16 | 1.62 |

| 8RED6 | 1/2 | 3/8 | 1.84 | 0.86 | 0.90 | 11/16 | 7/8 | 1.44 |

Female Elbow

| METRIC RANGE | Dimention in mm | ||||||||

|

Part

|

T

|

P

|

L1

|

M

|

C

|

D

|

F

|

G

|

H

|

|

N0

|

mm / a |

Length

|

Body

|

Nut

|

Body

|

||||

| 4mFE2 | 4 | 1/8 | 24.20 | 10.00 | 19.00 | 12 | 12 | 12.70 | 17.80 |

| 6mFE2 | 6 | 1/8 | 26.40 | 10.00 | 19.00 | 15.20 | 14.00 | 14.00 | 19.00 |

| 5mFE4 | 6 | 1/4 | 29.12 | 14.00 | 22.40 | 15.20 | 19.00 | 14.00 | 22.30 |

| 5mFE5 | 6 | 3/8 | 34.50 | 14.00 | 25.00 | 15.20 | 22.00 | 14.00 | 23.00 |

| 5mFE5 | 6 | 1/2 | 34.50 | 19.00 | 30.00 | 19.80 | 27.00 | 14.00 | 27.00 |

| 8mFE2 | 8 | 1/8 | 29.10 | 10.00 | 19.00 | 16.25 | 14.00 | 17.00 | 22.35 |

| 8mFE4 | 8 | 1/4 | 30.48 | 1400 | 22.35 | 16.26 | 19.00 | 17.00 | 23.20 |

| 5mFE5 | 8 | 3/8 | 33.50 | 14.00 | 24.00 | 16.26 | 22.00 | 17.00 | 25.00 |

| 5mFE5 | 8 | 1/2 | 3350 | 19.00 | 28.00 | 19.80 | 27.00 | 17.00 | 30.00 |

| 10mFE2 | 10 | 1/8 | 30.40 | 10.00 | 19.00 | 16.70 | 17.00 | 19.00 | 23.22 |

| 10mFE4 | 10 | 1/4 | 31.24 | 14.00 | 22.35 | 16.70 | 19.00 | 19.00 | 23.55 |

| 10mFE6 | 10 | 3/8 | 33.50 | 14.00 | 22.35 | 16.70 | 22.00 | 19.00 | 25.00 |

| 10mFE8 | 10 | 1/2 | 35.30 | 19.00 | 22.35 | 16.70 | 27.00 | 19.00 | 25.50 |

| 12mFE4 | 12 | 1/4 | 35.00 | 1400 | 22.35 | 22.86 | 22.00 | 22.00 | 25.00 |

| 12mFE6 | 12 | 3/8 | 36.32 | 14.00 | 22.35 | 22.86 | 22.00 | 22.00 | 25.00 |

| 12mFE8 | 12 | 1/2 | 38.60 | 19.00 | 28.45 | 22.86 | 27.00 | 22.00 | 25.00 |

| 16MFE8 | 16 | 1/2 | 38.60 | 19.00 | 28.50 | 22.86 | 27.00 | 27.00 | 28.50 |

Female Adaptor

| IMPERIAL RANGE | Dimensions in inches | ||||

|

Part NO

|

T

|

P

|

M

|

F

|

H

|

| 2ADF2 | 1/8 | 1/8 | 0.39 | 9/16 | 1-5/32 |

| 4ADF2 | 1/8 | 1/8 | 0.39 | 9/16 | 1-5/32 |

| 4ADF4 | 1/4 | 1/4 | 0.59 | 3/4 | 1-11/32 |

| 5ADF4 | 5/16 | 1/4 | 0.59 | 3/4 | 1-7/16 |

| 5ADF6 | 51/6 | 3/8 | 0.59 | 7/8 | 1-17/32 |

| 6ADF4 | 3/8 | 1/4 | 0.59 | 3/4 | 1-13.32 |

| 6ADF6 | 3/8 | 3/8 | 0.59 | 7/8 | 1-15/32 |

| 6ADF8 | 3/8 | 1/2 | 0.78 | 1-1/16 | 1-21/32 |

| 8ADF4 | 1/2 | 1/4 | 0.59 | 3/16 | 1-5/8 |

| 8ADF4 | 1/2 | 1/4 | 0.59 | 3/16 | 1-5/8 |

| 8ADF6 | 1/2 | 3/8 | 0.59 | 7/8 | 1-11/16 |

| BADF8 | 1/2 | 1/2 | 0.78 | 1-1/16 | 1-7/8 |

| 12ADF8 | 3/4 | 1/2 | 0.78 | 1-1/16 | 2.0 |

| 12ADF12 | 3/4 | 3/4 | 0.81 | 1-5/16 | 2-1/16 |

Male Adaptor

| METRIC RANGE | Dimensions in mm | ||||

|

Part No

|

T

|

P

|

M

|

F Body

|

L

|

| 4mADM2 | 4 | 1/8″ | 9.52 | 12 | 29.31 |

| 4mADM4 | 4 | 1/4″ | 14.29 | 14 | 34.13 |

| 6mADM2 | 6 | 1/8″ | 9.52 | 12 | 30.95 |

| 6mADM4 | 6 | 1/8″ | 14.29 | 14 | 35.72 |

| 6mADM6 | 6 | 3/8″ | 14.29 | 19 | 35.51 |

| 6MADM8 | 6 | 1/2″ | 19.05 | 24 | 42.07 |

| 8mADM2 | 8 | 1/8″ | 9.52 | 12 | 31.15 |

| 8mADM4 | 8 | 1/4″ | 14.29 | 14 | 37.31 |

| 8mADM6 | 8 | 3/8″ | 14.29 | 19 | 37.31 |

| 8mADM8 | 8 | 1/2″ | 19.05 | 24 | 42.86 |

| 10mADM2 | 10 | 1/8″ | 9.52 | 12 | 33.34 |

| 10mADM4 | 10 | 1/4″ | 14.29 | 14 | 39.10 |

| 10mADM5 | 10 | 3/8″ | 14.29 | 19 | 35.10 |

| 10mADM8 | 10 | 1/2″ | 19.05 | 24 | 42.55 |

| 12mADM4 | 12 | 1/4″ | 14.29 | 14 | 42.66 |

| 12mADM6 | 12 | 3/8″ | 14.29 | 19 | 44.45 |

| 16mADM6 | 16 | 3/8″ | 14.29 | 19 | 46.04 |

| 16mAnM8 | 16 | 1/2″ | 19.05 | 24 | 50.30 |

| 16mADM12 | 16 | 3/4″ | 19.05 | 27 | 51.59 |

| 20mADM8 | 20 | 1/2″ | 19.05 | 24 | 50.50 |

| 20mADM12 | 20 | 3/4″ | 19.05 | 27 | 51.59 |

| 20mADM16 | 20 | 1″ | 23.81 | 36 | 57.94 |

| 25mADM12 | 25 | 3/4″ | 19.05 | 27 | 57.94 |

| 25mADM16 | 25 | 1″ | 23.81 | 36 | 65.09 |

Union Cross

| METRIC RANGE | Dimention in mm | |||||||

|

Part

|

T

|

L1

|

D

|

F

|

G

|

H

|

J

|

L

|

|

N0

|

mm o/d |

Length

|

Body

|

Nut

|

Body

|

Body

|

||

| 4mUC | 4 | 26.15 | 14.29 | 12 | 12 | 19.00 | 38.00 | 52.30 |

| 6mUC | 6 | 27.20 | 15.88 | 12 | 14 | 19.60 | 39.60 | 54.40 |

| 8mUC | 8 | 29.70 | 16.67 | 14 | 17 | 22.20 | 44.40 | 59.40 |

| 10mUC | 10 | 30.80 | 17.46 | 14 | 19 | 23.10 | 46.20 | 61.60 |

| 12mUC | 12 | 35.00 | 23.02 | 17 | 22 | 24 | 49.80 | 70.00 |

| 16mUC | 16 | 36.39 | 24.61 | 24 | 27 | 26.19 | 52.39 | 72.78 |

Union Tee

| METRIC RANGE | Dimention in mm | |||||||

|

Part

|

T

|

L1

|

D

|

F

|

G

|

H

|

J

|

L

|

|

N0

|

mm o/d |

Length

|

Body

|

Nut

|

Body

|

Body

|

||

| 4mUC | 4 | 26.15 | 14.29 | 12 | 12 | 19.00 | 38.00 | 52.30 |

| 6mUC | 6 | 27.20 | 15.88 | 12 | 14 | 19.60 | 39.60 | 54.40 |

| 8mUC | 8 | 29.70 | 16.67 | 14 | 17 | 22.20 | 44.40 | 59.40 |

| 10mUC | 10 | 30.80 | 17.46 | 14 | 19 | 23.10 | 46.20 | 61.60 |

| 12mUC | 12 | 35.00 | 23.02 | 17 | 22 | 24 | 49.80 | 70.00 |

| 16mUC | 16 | 36.39 | 24.61 | 24 | 27 | 26.19 | 52.39 | 72.78 |

Male Branch Tee

| METRIC RANGE | Dimention in mm | |||||||

|

Part

|

T

|

L1

|

D

|

F

|

G

|

H

|

J

|

L

|

|

N0

|

mm o/d

|

Length

|

Body

|

Nut

|

Body

|

Body

|

||

| 4 | 4 | 26.15 | 14.29 | 12 | 12 | 19.00 | 38.00 | 52.30 |

| 6mTTT | 6 | 27.20 | 15.88 | 12 | 14 | 19.80 | 39.60 | 54.40 |

| 8mTTT | 8 | 29.70 | 16.67 | 14 | 17 | 22.20 | 44.40 | 59.40 |

| 10mTTT | 10 | 30.80 | 17.46 | 14 | 19 | 23.10 | 46.20 | 61.60 |

| 12mTTT | 12 | 35.00 | 23.02 | 19 | 22 | 24.90 | 49.80 | 70.00 |

| 16mTTT | 16 | 36.39 | 24.61 | 24 | 27 | 26.19 | 52.30 | 72.78 |

| 18mTTT | 18 | 39.37 | 24.61 | 27 | 30 | 29.37 | 58.74 | 78.74 |

| 20mTTT | 20 | 39.37 | 24.61 | 27 | 30 | 29.37 | 58.74 | 78.74 |

| 25mTTT | 25 | 45.24 | 30.96 | 32 | 41 | 33.54 | 67.08 | 90.48 |

Male Run Tee

| METRIC RANGE | Dimention in mm | ||||||||||

|

Part

|

T |

P

|

L1

|

M

|

C

|

F

|

G

|

H

|

J

|

L

|

|

|

No

|

mm o/d

|

Length

|

Body

|

Nut

|

Body

|

||||||

| 4mTTM1 | 4 | 1/6 | 26.15 | 9.53 | 19.3 | 12 | 12 | 19.05 | 38.10 | 52.30 | |

| 4mTTM2 | 4 | 1/8 | 26.15 | 9.53 | 19.53 | 12 | 12 | 19.05 | 38.10 | 52.30 | |

| 4mTTM | 4 | 1/4 | 26.15 | 14.29 | 23.9 | 12 | 12 | 19.05 | 38.10 | 52.30 | |

| 6mTTM | 6 | 1/8 | 27.21 | 9.53 | 19.3 | 12 | 14 | 19.80 | 39.60 | 54.42 | |

| 6mTTM4 | 6 | 1/4 | 27.21 | 14.29 | 23.9 | 12 | 14 | 19.80 | 39.60 | 54.42 | |

| 6mTTM6 | 6 | 3/8 | 28.73 | 14.29 | 25.4 | 14 | 14 | 21.33 | 42.66 | 57.46 | |

| 6mTTM8 | 6 | 1/2 | 30.51 | 19.05 | 32.0 | 19 | 14 | 23.10 | 43.20 | 61.00 | |

| 8mTTM2 | 8 | 1/8 | 29.70 | 9.53 | 20.8 | 14 | 17 | 22.22 | 44.44 | 59.40 | |

| 8mTTM4 | 8 | 1/4 | 29.70 | 14.29 | 25.4 | 14 | 17 | 22.22 | 44.44 | 59.40 | |

| 8mTTM6 | 8 | 3/8 | 29.70 | 14.29 | 25.4 | 14 | 17 | 22.22 | 44.44 | 59.40 | |

| 8mTTM8 | 8 | 1/2 | 31.50 | 19.50 | 32.0 | 19 | 17 | 24.00 | 48.00 | 63.00 | |

| 10mTTM2 | 10 | 1/8 | 30.80 | 9.53 | 20.8 | 14 | 19 | 23.10 | 46.20 | 61.60 | |

| 10mTTM | 10 | 1/4 | 30.80 | 14.29 | 25.4 | 14 | 19 | 23.10 | 46.20 | 61.60 | |

| 10mTTM6 | 10 | 3/8 | 30.80 | 14.29 | 25.4 | 14 | 19 | 23.10 | 46.20 | 61.60 | |

| 10mTTM8 | 10 | 1/2 | 32.59 | 19.05 | 32.0 | 19 | 19 | 24.89 | 49.78 | 65.18 | |

| 12mTTM4 | 12 | 1/4 | 34.99 | 14.29 | 27.4 | 19 | 22 | 24.89 | 49.78 | 69.98 | |

| 12mTTM6 | 12 | 3/8 | 32.59 | 14.29 | 27.4 | 19 | 22 | 24.89 | 49.78 | 65.18 | |

| 12mTTM8 | 12 | 1/2 | 32.59 | 19.05 | 32.0 | 19 | 22 | 24.89 | 49.78 | 65.18 | |

| 16mTMT8 | 16 | 1/2 | 36.39 | 19.05 | 34.9 | 24 | 27 | 26.19 | 52.39 | 72.78 | |

Nut

| METRIC RANGE | Dimensions in mm | |||||

|

Part

|

T mm

|

G

|

L

|

|||

| 4mN | 4 | 12 | 11.80 | |||

| 6mN | 6 | 14 | 12.70 | |||

| 8mN | 8 | 17 | 13.49 | |||

| 10mN | 10 | 19 | 14.29 | |||

| 12mN | 12 | 22 | 17.46 | |||

| 16mN | 16 | 27 | 17.46 | |||

| 18mN | 18 | 30 | 17.46 | |||

| 20mN | 20 | 30 | 17.46 | |||

| 25mN | 25 | 41 | 20.64 | |||

Ferrules

| METRIAL RANGE | Dimensions in mm | ||||

|

Back Ferrule Part No

|

T o/d

|

Front Ferrule Part No

|

|||

| 4mBF | 4 | 4mFF | |||

| 6mBF | 6 | 6mFF | |||

| 8mBF | 8 | 8mFF | |||

| 10mBF | 10 | 10mFF | |||

| 12mBF | 12 | 12mFF | |||

| 16mBF | 16 | 16mFF | |||

| 18mBF | 18 | 18mFF | |||

| 20mBF | 20 | 20mFF | |||

| 25mBF | 25 | 25mFF | |||